When the following association were founded : the NACE (National Association of Corrosion Engineers) in the USA in 1953, the AIAC (Association des Ingénieurs en Anticorrosion) in 1954 then the CEFRACOR (Centre Français de la Corrosion) in 1960 in France, and the EFC (Fédération Européenne de Corrosion) in 1955, cathodic protection really started to become more important. However it was still often considered as mysterious by the non-specialists. The demystification happened during the Sixties, with the help of associations of corrosionnists and the first technical manuals.

The applications in some Western Europe countries like France mainly referred to some buried pipelines and piers. Moreover, there were some applications for reinforced concrete piping (Bonna pipes ®).

The real development of cathodic protection for the buried pipelines took place with the development of the refineries and gas and petroleum products transport. In 1955, only 1000 km of major gas pipelines existed for France, Germany and Italy, compared to approximately 300 000 km today! In marine applications, there were then undoubtedly some cases in the military navy in Europe (real development in the Sixties). Offshore, no oil production had started in North Sea or in other sites such as Adriatic Sea or the Gulf of Guinea. Offshore cathodic protection started in Caspian sea in the 50s.

In Great Britain, cathodic protection became an industrial process recognized during the 1950s. For example, for the Rosneath and Harwich piers (impressed current with suspended Fe-Si anodes). In Germany, the first cathodic protection system was installed in 1952 and the first drainage in 1953. E.On Ruhrgas has systematically employed cathodic protection since 1958 (3000 km were not protected since their origin).

Jehan Changarnier, Roger Legrand, Bernard Heuzé and George Poirier were pioneers for the application of this technique in France for gas, hydrocarbon and water pipelines since the Fifties. At their instigation, there were thus at the beginning of the Sixties more than 20 000 km of buried pipes under cathodic protection (1000 km for Gaz de France, 2500 km for Gaz du Sud-Ouest, 5000 km for water, a thousand for the liquid hydrocarbon pipelines such as Le Havre – Paris, Donges-Metz, the South-European pipeline).

In Romania, a Group for the application of cathodic protection was created in 1954 at the Oil Research Institute (ICEP), then others for water and gas networks in Bucharest. In the USSR, almost all the major pipelines were equipped with cathodic protection since the Sixties.

In South Africa, first application for the magnesium anodes for the Johannesburg gas lines in the Fifties and for the impressed current at the beginning of the Sixties on the pipelines.

The applications of cathodic protection in the Fifties were most widespread in the USA:

- Pipelines, especially at the beginning of the Seventies after the regulations of the DOT 49CFR Part 192 (gas) and 195 (liquids)

- Some uses on the boats (especially US Navy), more widespread since 1960

- Impressed current in the harbours such as New York and Boston

- Some marginal cases of use for storage tanks, wells, buried piping,..

- Many water towers protected by impressed current with anodes replaced every 8 months. Some Mg anodes in the swimming pools, radiator water tanks for heat exchangers

- Some examples in the concrete sector.

At that time, the cathodic protection criteria established by a British " Joint Committee " were:

- Protection threshold of -0.850 V/Cu-CuSO 4 in aerobic conditions and -0.950 V/Cu-CuSO 4 in anaerobic conditions

- All the potentials were measured in " ON conditions " (without turning off the current)

- The potential was limited to -2 V to avoid the separation of coatings

- A 20 mV maximum positive variation due to the electrical interferences was authorized.

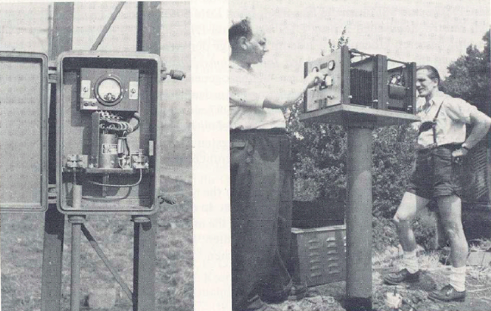

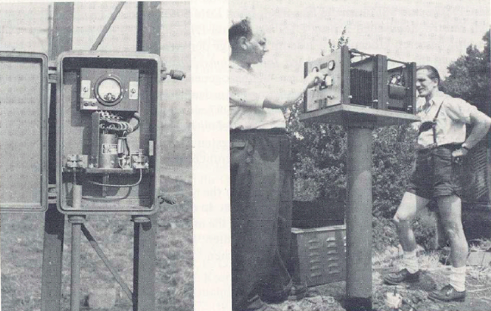

The best multimeters (analogical) had an internal resistance of 150 000 Ω/V. The only method enabling the detection of the coating defects on buried pipelines was the Pearson method, used in the USA, in GB and the USSR since the Fifties.