- FR

- EN

Cathodic protection design for buried structures

General information about the design of an installation

The lifespan of a cathodic protection installation is about 15 or 20 years, because it is better to space out the earthworks.

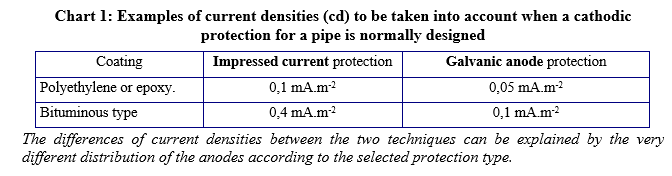

The current density to be taken into account when an installation is designed depends on the type of cathodic protection and the coating on the pipes. Chart 1 gives an example of these current densities for a coated steel. For a non-alloy steel that is not coated, the current density to be taken into account depends on the humidity of the ground.

For protection by galvanic anodes, it is a zinc or magnesium alloy surrounded by a regulating mixture called " backfill " made from bentonite and calcium sulphate. The aluminium anodes cannot be used because the grounds generally do not contain enough chlorides ions to avoid their passivation which leads to a fall of the galvanic current flow.

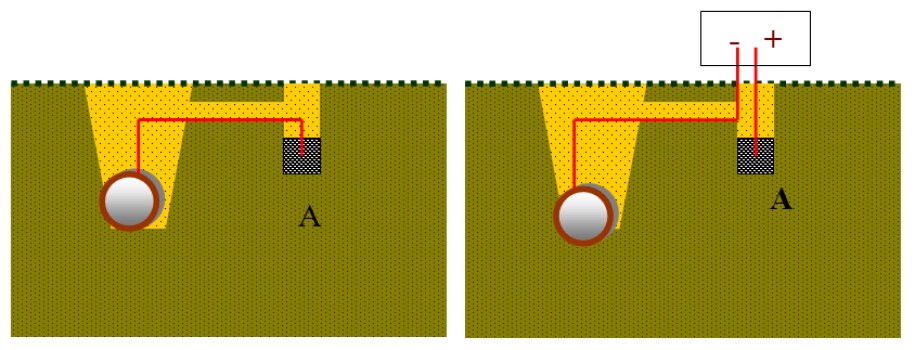

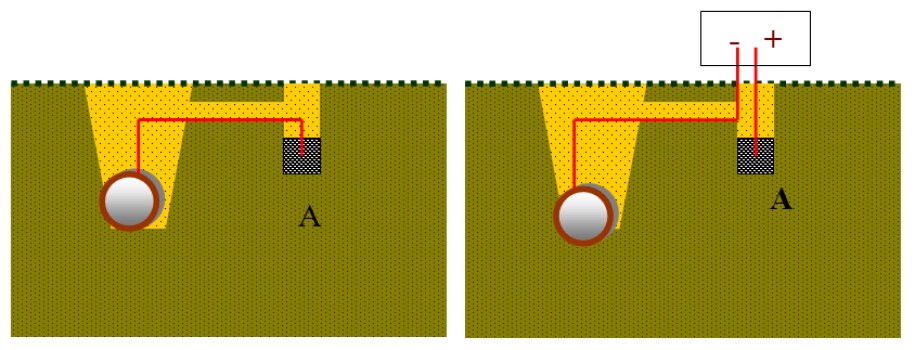

Electrical cables are fixed on the buried structure, and regularly spaced out to allow measurements of potential on the surface, from a measurement box.

Interactions with nearby structures

The place of the anodes must take into account that there may be metal structures in the vicinity of the one we wish to protect. A ground pipe can also be influenced (electromagnetic induction) by a very high voltage powerline, near and parallel. On the defects, the steel in contact with the ground can then corrode. In this case, it is necessary to put this pipe at the ground, generally at the ends of its part that is parallel to the line, while blocking the passage of the protection direct current in the connection thus created.

The railways with electrical current are also a source of disturbance for the cathodic protection of the pipes in their vicinity. It is generally necessary to install stray current " drains " in order to avoid any current leakage from the structure to be protected towards the ground.